Take $10 off select small waterer parts orders of $100 or more with coupon code WATERERPARTS

SHIPPING - All products ship within the same or next business day unless noted.

NORMAL Shipping takes between 2-5 days, Freight 1-2 weeks. Need a freight quote on large items? Click Here.

Paddock Slab - 466 pieces Custom Order Chris Brockmeyer

Pallet of 100 pieces will cover approximately 215.2 ft². Contact us for best shipping options.

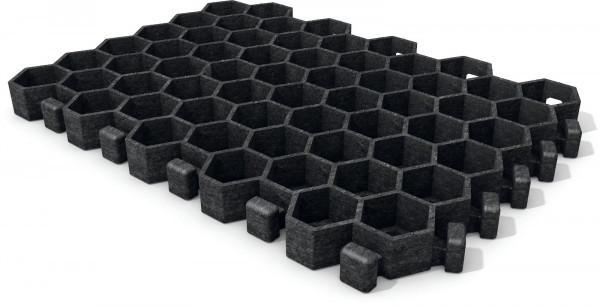

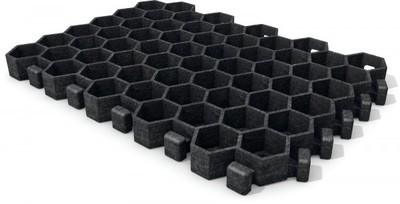

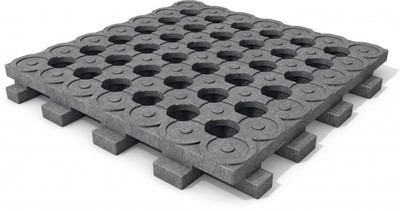

The Hahn Plastics Paddock Slab Mesh Structure features a rigid interlocking system. The quantity of 100 will be a perfect solution for paddocks, riding arenas, exercise runs & feeding areas. Made of 100% recycled plastic, the slabs feature a manufacturers 20-year warranty.

FEATURES

- Ideal aperture size for horses

- Excellent water permeation through the surface

- Durable, non-rotting and weather resistant

- High stability due to strong web

- Frost and UV-resistant

- Low maintenance and cost effective throughout the product life

- The lightweight interlocking design enables ease and speed of installation

- Paddock Slab reduces the carbon footprint of a project and it is completely recyclable

All the tested Paddock Slabs are capable of bearing the passage of a category SLW 60 heavy duty truck. Sufficient load bearing capacity of the ground according to the provisions of ZTV SoB 04 [2] is a prerequisite. The tested ground reinforcements are suited for application in fire lanes and parking areas for heavy utility vehicles.

LAYING INSTRUCTIONS

A permeable layer (approx. 20–25 cm (7.87–9.84”)) of crushed rock, lava or gravel 2 is applied to soil with good bearing capacity 1 and compacted afterwards. A 2–4 cm (0.79–1.57”) equalising layer of grit 3 is subsequently applied and levelled.

The slab 5 serves as separating layer. It is filled with grit, sand or gravel and prevents the mixing of base and footing layer. Separation can be improved by placing a permeable fibrous web 4 under the slab.

Finally, the footing 6 is applied. It may consist of sand, wood chips, fabric based or similar material.

For use in less stressed areas (paddocks, feedlots, access paths) the sub-base can be reduced according to the expected strain or the slab can even be placed directly on natural ground.

It cannot be guaranteed though that the slab will not sink into the ground.